When you have several million dollars’ worth of equipment towering 300 feet above the ground, the last thing you want to worry about is bearing failure. Scheerer Bearing provides high-performance bearing solutions for wind turbine manufacturers, designed to meet the very unique requirements of these ultra-large machines.

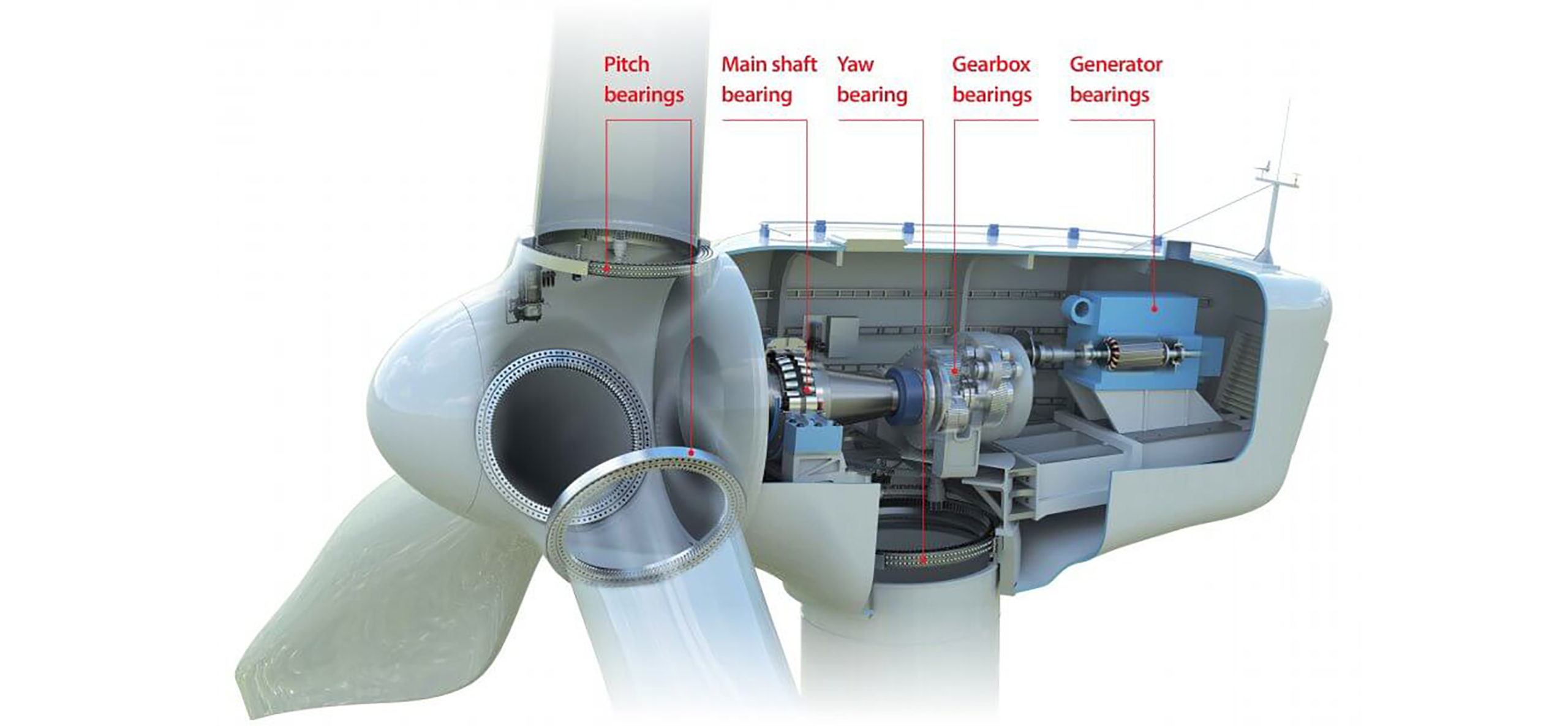

Scheerer has bearing solutions for every position in your turbine, from the main shaft, to the gearbox, to the large diameter pitch and yaw slewing ring bearings. Utilizing application specific features such as black oxide and tungsten carbide surface treatments and case carburized components, our bearings can extend the life of your wind turbines and increase their overall performance.

High Load Cylindrical Roller Bearings

Full complement cylindrical roller bearings provide the highest possible radial load capacities by maximizing the number of rollers. These bearings are ideally suited to critical applications where the weight must be lifted to considerable heights.

Tapered Roller Bearings for Wind Turbines

Wind turbine and industrial windmill manufacturers usually pair tapered roller bearings to handle thrust loads in both directions. Tapered roller bearing assemblies can be adjusted for preload or clearance during assembly. Preload can offer gearbox stability with load sharing between rows and predicted roller-to-race interactions. Clearance or endplay would compensate for thermal growth without any increase in roller friction.

Superior Performance for the Most Demanding Industrial Applications.

Get Our Competitive Advantage.

Bearings are designed to take a beating in tough environments. With proper design and maintenance, your corrugator equipment bearings can ensure consistent high-performance in high-stress environments.

Companies across the paper industry seek long-term value through precision engineering. Scheerer provides that kind of detailed engineering to manufacturers and processing companies throughout the corrugated, paper, pulp and board manufacturing sector.

Partner with Scheerer.

Perform Better.

Call Scheerer direct: 215-443-5252

Get a Preliminary Estimate.

Send us Your Specifications.

- Imperial or Metric

- Any special designs and variants (NU, NCF, RAD, etc.)

- Bore Dimensions (d)

- Outer Diameter (D)

- Width of the Bearing (B)

- Required Load Capacity (C & Co)

Our engineering team routinely reviews proposed CAD designs from customers. We are available to share insights you may not have considered.

Scheerer Provides the Full Suite of Wind Turbine Bearings

Scheerer Bearing has been an energy industry partner since 1963. Our comprehensive, state-of-the-art bearing product line is ideally suited for the wind turbine market. Scheerer offers decades of engineering expertise focused exclusively on the highest-performance ball and roller bearing design and bearing assemblies. Scheerer engineers will work closely with your design team, ensuring all application requirements are successfully addressed and finalized.

A Global Supplier of Wind Turbine Bearings

When you choose a bearing manufacturer, you require commitment to design excellence and high quality standards. Scheerer brings you decades of engineering expertise focused exclusively on the highest performance ball and roller bearing designs and bearing assemblies. We help OEMs maximize output efficiency by tailoring bearing design to the unique functional needs of your equipment. As a worldwide supplier of bearings used in the wind energy industry, Scheerer has decades of engineering knowledge designing ball bearings, roller bearing, spherical roller bearings and slewing ring bearing assemblies.

Contact Scheerer Bearing Direct at (800) 443-5252